Autonomous driving system, full automation of tractor driving during spraying, mowing and field work.

Unmanned operation and driving of any tractor in all conditions.

Precise navigation using GPS-RTK systems and local vision devices.

Autonomous driving system, full automation of tractor driving during spraying, mowing and field work.

Unmanned operation and driving of any tractor in all conditions.

Precise navigation using GPS-RTK systems and local vision devices.

Automatic and unmanned control of tractor’s and implement’s drive

In order to program the device to work, the user has

several methods to choose from, to be used as needed, they are:

Recording and saving of a reference route; subsequent runs will be performed automatically with reference to the data recorded when creating the program.

Setting of points A and B on the map, determination of the section along which the tractor will drive and setting the distance from the section A-B along which the tractor will perform parallel runs.

Circle around the field (applies to flat areas not planted with trees) to define the outer perimeter of the plot; the system will perform a simulation and design a spiral route in order to cover the entire area located within the circumference.

Uploading digital maps of plantations with marked reference points, plantings and fences.

Autonomous driving kit prepared to be installed on every tractor’s model. The device allows to automate the driving of the tractor during orchard and field work, eliminating the presence of the tractor driver.

Tractors equipped with this system are ready for independent, unmanned fully autonomous driving.

Intended for use with tractors with the following parameters:

Autonomous tractor ready for orchard and vineyard work. A specially configured tractor equipped with the Auto Drive autonomous driving system. When configuring this set of equipment, we were guided by the needs of modern fruit growers and gardeners, bearing in mind the needs of ergonomics, dimensions, power and tractor equipment, as well as the width of the currently used plantings.

The system that the tractor is equipped with has the same functions as the Auto Drive system kit for mounting on any tractor. Especially:

The ability to fully control the operating parameters of any tractor is provided by specially prepared drives, sensors and control units, installed in the appropriate places of the machine. Thanks to the unification of the system components used by GOtrack, each tractor is equipped with standardized GOtrack components.

The system is completely electric, it does not use any of the tractor’s pneumatic and hydraulic systems as a source. The location of the individual components of the Auto DRIVE system is shown in the graphic below.

Each kit includes a wireless sprayer module

which controls valves and sensors build in the sprayer.

The RTK corrections reference station is used to generate geo-location corrections for GOtrack device users and more.

The device is designed to work with navigation devices that require high precision. It generates RTK location corrections with an accuracy of 2 cm.

Having your own base station eliminates the need to purchase a subscription access to RTK services.

The EHR module digitally controls the position of the tractor’s rear hitch. It is controlled by a large readable panel mounted in the cabin and buttons on the rear fender.

The device is used in tractors that have not been factory-equipped with an electronically controlled lift.

Thanks to this solution, work such as mowing, harrowing, plowing, connecting implement machines becomes much more efficient and easier to use.

The product is available as a standalone device separate from other GOtrack products and as an additional module for users of the Auto DRIVE system.

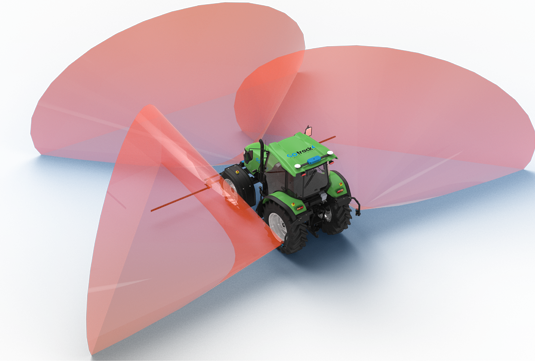

The ODC obstacle detection camera is a solution designed to detect and recognize obstacles in the vicinity of a moving vehicle.

The device uses a multi-level spectrum of space and object detection. Specially prepared algorithms using artificial intelligence effectively recognize and identify the type and location of objects, i.e. people, animals, trees, vehicles, fences.

The ODC camera is used as an additional module in the GOtrack Auto DRIVE autonomous driving systems.

Increase the efficiency of orchard treatments and works. Control your employees’ work remotely. Respect your time.

Universal GOtrack kits provide at least the same functionality as ready-made solutions, and are obviously cheaper.

We design our products based on the stringent safety requirements set for this type of devices.

Thanks to GOtrack, complex processes can be controlled through an easy-to-use interface with a minimal amount of buttons.

Off-the-shelf solutions and universal mounting ensure short standby time for commissioning the system at the Customer’s site.

GOtrack solutions can be integrated with all types of machinery and equipment available on the market, without the need to interfere with the machines’ internal systems.

Autonomous work when

driving and planting plants

Autonomous mowing

Autonomous spraying of plantations

Find out more